Want to sell something?

Create your

MULTIVENDOR SITE

You are one step from making real money

Created

1

Want to Buy best products

Check Latest Deals

We've gone over everything you could possibly want

to know about our site. You are one step

closer to success

to know about our site. You are one step

closer to success

Added to wishlistRemoved from wishlist 36

$380.99

Added to wishlistRemoved from wishlist 35

$20.00

Added to wishlistRemoved from wishlist 48

$29.99

Added to wishlistRemoved from wishlist 85

11%

Added to wishlistRemoved from wishlist 31

$229.99

Added to wishlistRemoved from wishlist 28

$699.99

Added to wishlistRemoved from wishlist 10

$1,799.99

Added to wishlistRemoved from wishlist 8

$399.00

Added to wishlistRemoved from wishlist 26

$199.00

Added to wishlistRemoved from wishlist 21

$199.95

Added to wishlistRemoved from wishlist 23

$249.99

Added to wishlistRemoved from wishlist 17

$599.99

Found something interesting ?

Get better results by upgrading today!

Want to Buy best products

Choose Category

This is my subheading

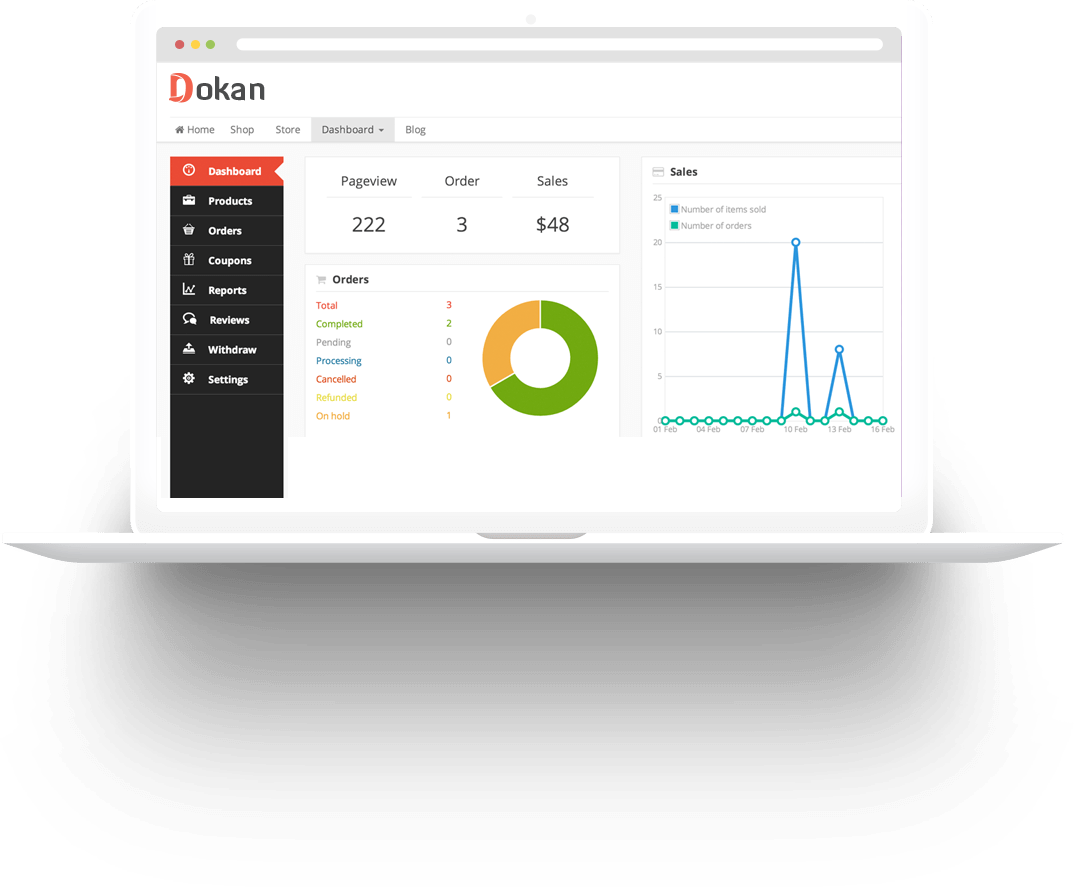

Let's See How It Works

We've gone over everything you could possibly want

to know about our theme. You are one step

closer to success

to know about our theme. You are one step

closer to success

1

Choose Plan

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolor tempor incididunt

Register

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolor tempor incididunt

2

Add your logo

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolor tempor incididunt

3

Start selling

Consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolor tempor incididunt

4

This is my subheading

Latest from Our Blog

We've gone over everything you could possibly want

to know about our theme. You are one step

closer to success

to know about our theme. You are one step

closer to success

Uncategorized

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Coupons and deals

Coupon for Samsung TV give 10%

Every hour, one lucky customer will get 100% cashback on Delhi metro card ...